SAVE RESOURCES

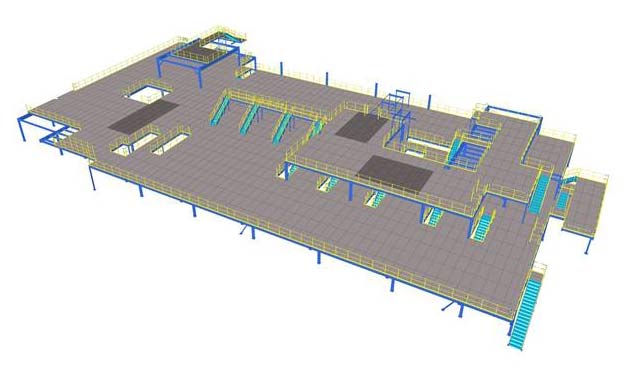

Save space - with logistics platforms

After placing an order in an online shop, the goods usually pass through a logistics center. There the articles are picked, packed and shipped. Today it is standard that these activities are carried out with the help of automated conveyor and sorting systems. Our logistics platforms are used to ensure that the required buildings do not become too large and expensive. In short: The technology is shifted to a higher level so that people can work below it.

TECHNICAL DETAILS

Setup of our logistics

platforms

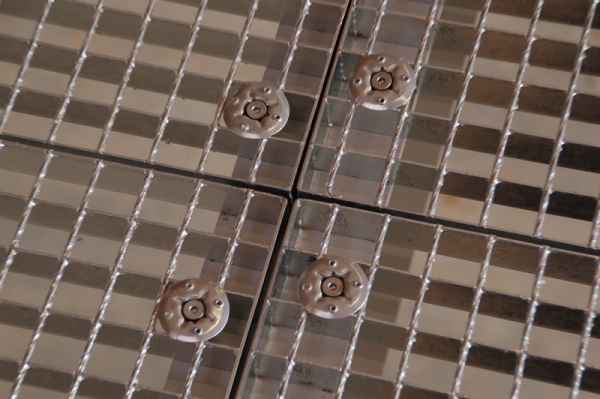

The supporting structure consists of robust, hot-rolled steel (S235). Standard coverings are chipboard or grating.

We use chipboard with a melamine resin coating on both sides. From above with dirt-repellent and anti-slip effect (R9/R10). White and smooth underneath. Particle board is ergonomically beneficial for maintenance areas and work surfaces.

Gratings have advantages in terms of sprinkler, lighting and ventilation and do not introduce additional fire loads into the structures. Stairs and railings comply with DIN EN 14 122 and BGR 234. Railings made of rectangular tubing with handrails made of round tubing are our standard.

The stair treads are made of grating as standard, but they can also be made of checker plates or wood.

Pallet locks can be used in the railing. This makes it possible to transport goods on pallets through the railings from top to bottom without the risk of falling.

Ourstrengthscompetencesin this area are:

Expertise and experience

Planning with precision

Short delivery time

These facts speak for a logistics platform of IBW

less steel supports - chip widths up to 10m

individual payloads - 200 to 500 kg/m²

beams with low building height, if required

Multi-storey construction possible

Platforms suitable for hand pallet truck*

Steel parts in RAL colour or hot-dip galvanized

Our references

Request your individual offer now.

- Size

- Load capacity

- Span of beams / grid of columns

- Type of covering